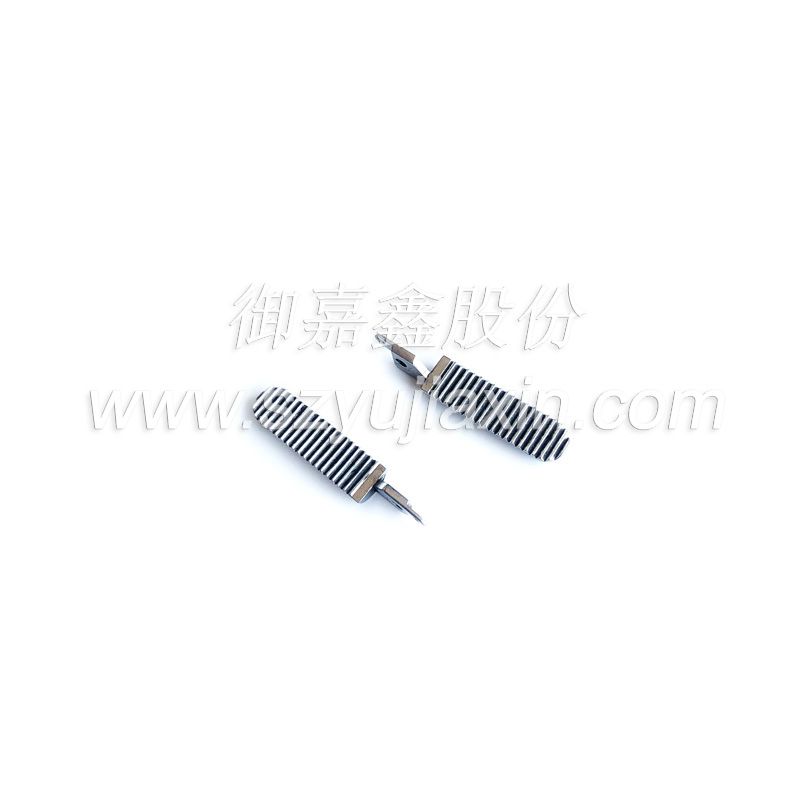

Metal powder injection molding (MIM) is an advanced manufacturing technology that combines the principles of plastic injection molding with powder metallurgy. This process allows for the production of complex and high-precision metal components, such as surgical blade tips. Here's a detailed description of the metal powder injection molding process for surgical blade tips:

Material Preparation: The first step involves selecting the appropriate metal powder for surgical blade tips. Commonly used metal powders include stainless steel, cobalt-chromium alloys, among others. These powders undergo meticulous sieving and mixing to ensure uniformity of composition and particle size.

Feedstock Formulation: The metal powder is then combined with an organic binder to create a feedstock that exhibits suitable flow properties. The type and amount of binder are carefully controlled to maintain consistency and stability during the injection molding process.

Injection Molding: The feedstock is injected into a precision-designed mold under high pressure. As the feedstock flows into the mold cavity, it adopts the desired shape of the surgical blade tip.

Debinding: After injection molding, the organic binder needs to be removed from the part. This debinding process is typically carried out in a controlled thermal environment, where the binder is gradually volatilized from the metal powder.

Sintering: Once debinding is complete, the surgical blade tip undergoes sintering to achieve the desired mechanical properties. During sintering, the metal powder particles fuse together through atomic diffusion, creating a dense and strong metal structure.

Post-Processing: Following sintering, the surgical blade tip may require additional post-processing steps such as grinding, polishing, or other finishing operations to achieve the desired surface roughness and precision.

Quality Inspection: Finally, the surgical blade tip undergoes rigorous quality inspection to ensure compliance with medical standards. This inspection covers dimensions, surface quality, mechanical properties, and other critical parameters.

The metal powder injection molding process offers advantages such as shortened manufacturing cycles, high material utilization, and precision production, making it an ideal choice for manufacturing surgical blade tips and other complex medical device components.